Dynamic Rollover Fixture Design and Testing of Dummy-Occupied Vehicles (JRS 2003, JRS II 2011, Nash Carousel) | Patents | Publications

CfIR developed test fixtures for dynamic rollover testing of dummy-occupied vehicles:-

1. Jordan Rollover System JRS 2003,

2. Jordan Rollover System JRS II 2011,

3. Nash Carousel 2018

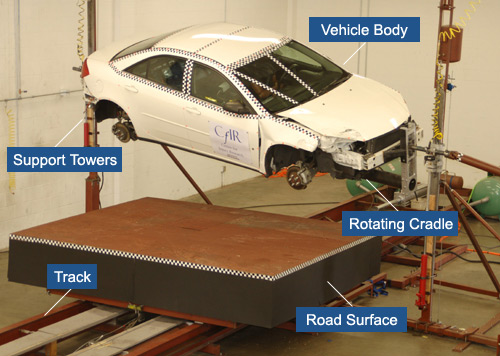

JRS Concept: The JRS is a versatile, repeatable rollover testing system capable of assessing vehicle structural design and performance, restraint system performance in rollovers, and rollover occupant kinematics and ejection. A full suite of instrumentation in the test vehicle and on the fixture allow for quantitative analysis of rollover forces and structural performance.The patented dynamic rollover test fixture simulates the rollover impact of a vehicle with a movind road bed. The vehicle is supported by towers at each end and dropped to the road bed for near and far side roof crush forces.

JRS Functionality: The system allows for repeatable tests in which various rollover parameters including pitch, yaw, roll rate, drop height, and contact angle can be altered and controlled. The JRS can also be used to conduct tests on component parts like rollover sensor triggering, side-curtain airbags, pretensioners on belts and spit tests to name a few.

JRS I Fixture for Dynamic Testing

JRS I Fixture for Dynamic TestingJRS 2003 Fixture Test Results: The matched pair tests on the JRS clearly demonstrate the reduction in injury potential with a strengthened roof structure. In our most recent tests, the roof intrusion was reduced by approximately 80%. The intrusion velocity was decreased by approxiamtely 50%. With these reductions which can be accomplished by reasonable, engineering alternative designs, the rollover occupant protection is greatly enhanced.

CfIR Proposed a New Occupant Protection Rating System: We have conducted extensive testing that provides a basis for such a rating. In particular the JRS dynamic rollover test results, in conjunction with NHTSA and IIHS statistical analyses, and the biomechanical injury correlation studies¹ provide that basis. A consumer rollover rating system is long overdue. The best way to rate the crashworthiness injury potential of vehicles in rollovers is by utilizing a JRS dynamic test. Rating vehicles simply by FMVSS 216 gives grossly misleading (both over and understated) injury rate results.² CfIR's proposed system includes a factored and weighted analysis by fatality rate and vehicle performance frequency in all major accident modes.

JRS Ratings: JRS dynamic tests were performed on 10 vehicles. Three of the vehicles tested earned “good” ratings, two were “acceptable”, two were “marginal” and three were rated “poor”.

JRS II 2011: Two improved versions of the JRS have been built for research at the University of New South Wales in Sidney, AU and at UVA in Charlottesville, VA.

UNSW JRS II Fixture

UNSW JRS II Fixture

Nash Carousel 2018: This invention is a device and procedure for testing wheeled vehicles to observe and document a vehicle's dynamic performance and occupant motion prior to and during single or multiple rollovers, assessing the vehicle's occupant restraint system performance - including deployable restraint - triggering - under rollover conditions, and determining the vehicle's occupant compartment integrity and occupant protection performance leading up to and during a rollover. The device of this invention can also be used as a rotating test sled that imparts high levels of longitudinal acceleration and lateral forces on a test object yawing about an orthogonal axis. The device of this investion is superior to current dynamic rollover test devices in that it requires neither that significant parts be removed from the test vehicle nor that any type of frame or carriage be attached to the vehicle. It also can realistically simulate the pre-roll and first roll conditions as applied to a vehicle and its occupants that are typical of actual rollovers.